Pile Set Monitoring

PILE SET MONITORING

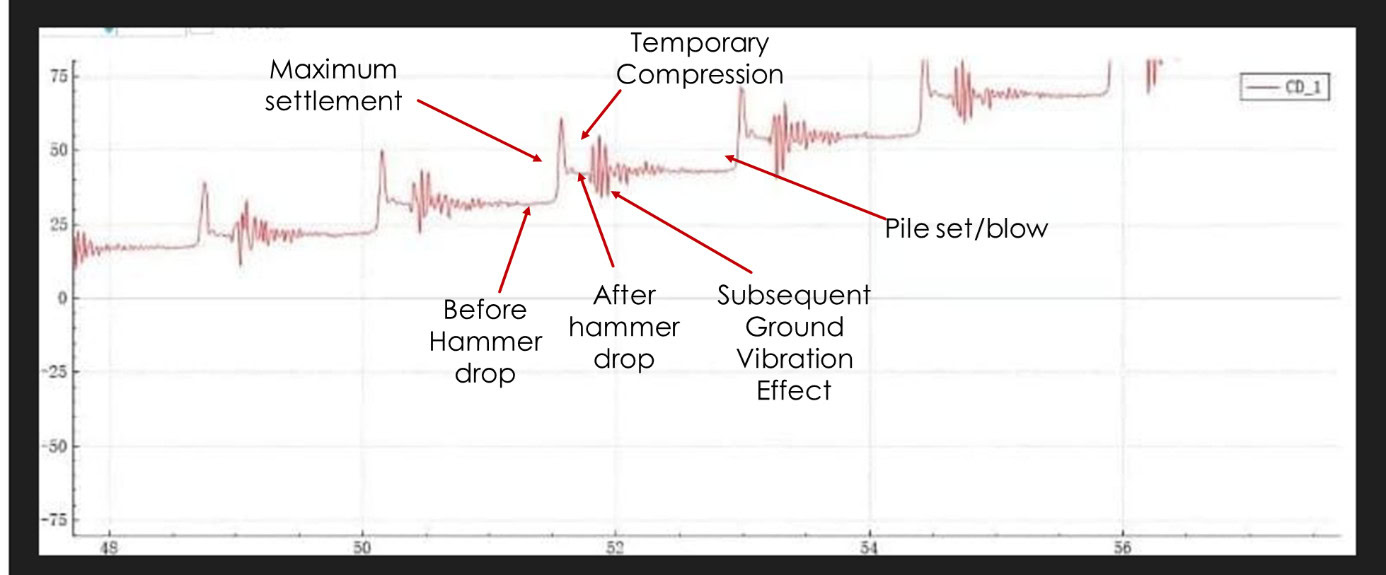

Pile set monitoring is an essential part of pile driving operations used to verify that each pile has achieved the required bearing capacity. The pile set is typically expressed as the permanent penetration (in millimetres) for 10 hammer blows, recorded at the final stage of driving.

Traditionally, measurements are taken manually and plotted using a pencil and graph paper. While this method is simple and widely practiced, it poses several challenges including safety risks, inconsistent readings, and limited quality control due to human error and the difficult working environment near the pile head.

Modern pile set monitoring solutions such as the Non Contact Deflection Tester provide a safer and more accurate alternative. This system measures the displacement of the pile during driving, allowing for dynamic analysis of the process. Parameters such as maximum displacement, temporary pile compression, and final displacement at the end of each blow can be recorded in real time. From this displacement data, velocity and acceleration curves can also be generated for further assessment.

BENEFITS:

- Accurate and reliable – Meets the practical measurement requirements for typical pile set monitoring

- Safe and efficient – Eliminates dangerous manual operations near the pile head

- Intelligent and consistent – Reduces human error, requires no physical targets, and offers a wide field of view for continuous, repeatable monitoring.